Search This Supplers Products:MBBR MediaAeration SystemRAS SystemTube settlerSmart Screw PressTurbo Blower

High Pressure Multistage Submersible Sewage Pumps For Textile And Dyeing Wastewater Treatment

- group name

- Sewage Pump

- Min Order

- 1 piece

- brand name

- AquaSust Wastewater Treatment Solutions

- model

- Sewage Pumps

- Nearest port for product export

- shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, D/P D/A

- update time

- Sat, 14 Feb 2026 20:01:16 GMT

Packging & Delivery

-

Min Order1 piece

Briefing

RAS System Supplier: High Pressure Submersible Pumps for Efficient Wastewater Treatment.

Detailed

Sewage Pumps Introdtion:

Categories: Sewage Pumps

Brand: AquaSust

Power Source: Electric

Structure: Multistage Pump

Warranty: 3 years

Model Number: Water Pumps

Outlet Size: Customer

Power: Customer

motor: Customer

Application: Wastewater treatment

Certification: RoHS, ce, IECEE

Size: 60*25*30CM

Weight: 32KG

Warranty: one year

MOQ: 1

Aquasust Sewage Pumps Advantages:

1. WQ/QW submersible pump sewage is developed with itenational advanced technology. It has been widely used in industrial, mining, construction, hospital, municipal engineering, garden, fountain, sewage treatment, chemical ,define effluent,tertiary sewage treatment , anaerobic wastewater treatment and other industries for more than ten years

2. The sewage pump submersible overcurrent parts are all made of sanes steel precision casting, which has the carateristis of no pllution and corosion rsistnce, and expands the application fields of water supply , aerobic wastewater treatment and drainage

3. The sewage water pump is made of ellent sainles steel 304/316 material. It has pure texture and beatiul appearance, which reduces secondary pllution and fuly meets the requirements of national geen environmental protection for primary sewage treatment

4. The drainage sewage pump is enegficient, reasonable in sructure, non-blocking and ani-winding, and has the charateristics of safe and reliable operation and long service life.The dual-rail automatic coupling device is equipped as needed to failiate the inallatioan tertiary treatment of sewage

5. The mechanical seal adopts double end sealing material, and uses high-quality hard aly such as tungsten carbide,and runs in the oil chamber for a long time, which Can make the stainless steel sewage water pump run continuously for more than 10,000 hours for secondary sewage treatment

These advantages make the sewage pump the preferred equipment for many industrial applications, especially where large quantities of wastewater or sludge need to be processed on a continuous basis.

Product Parameters

|

PARAMETERS

|

|||||

|

Model

|

Flow(m3/h) | Head(m) | Power(KW) | Hydraulic Pressure( mpa ) | Weight(KGS) |

|

50WQ10-10-0.75

|

10 | 10 | 0.75 | 60*25*30 | 28 |

|

50WQ7-15-1.1

|

7 | 15 | 1.1 | 60*25*30 | 30 |

50WQ10-15-1.1 | 10 | 15 | 1.1 | 60*25*30 | 30 |

25WQ5-22-1.1 | 5 | 22 | 1.1 | 60*25*30 | 32 |

65WQ20-10-1.5 | 20 | 10 | 1.5 | 60*25*30 | 40 |

80WQ40-7-1.5 | 40 | 7 | 1.5 | 60*25*30 | 42 |

100WQ50-5-1.5 | 50 | 5 | 1.5 | 60*25*30 | 44 |

80WQ40-16-4 | 40 | 18 | 4 | 71*30*33 | 64 |

100WQ60-12-4 | 60 | 13 | 4 | 71*30*33 | 66 |

100WQ80-10-4 | 80 | 12 | 4 | 71*30*33 | 66 |

80WQ40-28-7.5 | 40 | 40 | 7.5 | 86*34*38 | 108 |

100WQ65-22-7.5 | 65 | 30 | 7.5 | 86*34*38 | 110 |

Aquasust Sewage Pumps in Textile And Dyeing Wastewater Treatment Application

1. Wastewater transfer and lifting

Sump pumps are firstly used for wastewater transfer and lifting in textile dyeing and printing wastewater treatment. Textile dyeing wastewater needs to flow between several treatment stages, for example, from the catchment tank to the pretreatment tank, and then from the pretreatment tank to the biochemical treatment unit. Sump pumps ensure smooth and efficient transfer and lifting of wastewater between these stages.

2. Handling high wastewater flows

The textile printing and dyeing industry usually produces a large amount of wastewater, sewage pumps can handle high-flow wastewater to ensure the stable operation of the wastewater treatment system, to meet the demand for wastewater discharging and treatment in the production process.

3. Treatment of wastewater containing solids and fibers

Textile printing and dyeing wastewater contains a large number of fibers, dye particles and other solids, sewage pumps designed to take into account the characteristics of the anti-clogging, can effectively deal with wastewater containing solids and fibers, to prevent clogging of pumps and pipelines, to ensure that the wastewater treatment system operates smoothly.

4. Chemical dosing and mixing

In the process of wastewater treatment, often need to add chemicals for pretreatment or neutralization. Sewage pumps can mix chemicals and wastewater uniformly to ensure the effective distribution of chemicals in wastewater to improve the treatment effect. For example, it plays a key role in processes such as flocculation, sedimentation and neutralization.

5. Sludge transfer

Sewage pumps are not only used for transferring and lifting wastewater, but also for transferring sludge generated during the treatment process. For example, transferring sludge between settling tanks, thickening tanks and dewatering equipment ensures efficient operation of the sludge treatment process and reduces the difficulty of sludge treatment and disposal.

6. Improve the reliability of the treatment system

Efficient sewage pumps ensure stable operation of the wastewater treatment system and reduce system downtime due to equipment failure. Regular maintenance and use of high-quality sewage pumps can improve the reliability and service life of the entire wastewater treatment system.

Sewage Pupm Installation Instructions:

1.Check whether pump fasteners are loosen and whether the pump body runner is blocked by foreign matters before installation to avoid damage of impeller and pump body in running wastewater sludge.

2.Supporters for the outlet pipe should be installed separately so that the weight will not be added to the pump so as to prevent it from deformation. The pump base for both movable and fixed installation must be leveled by a level. After the base is ready, install the pump on the base and then use a level to check horizontal and vertical situation between the pump and motor shaft. Use the iron shim to change the height of the base if the pump is out of level. Then grout the base and anchor bolt holes by pouring the concrete into the grout hole,reduce wastewater treatment cost.

3.Sewage treatment stages has levelness of the coupling device should be calibrated by a level when coupling installation is adopted. Horizontal level tolerance should not exceed 0.1mm/m. Use the measure gage to calibrate parallelism of two coupling rods to ensure the parallelism tolerance will not exceed 0.2mm/m.

4.Tighten the anchor bolt to make sure there is no looseness between the anchor bolt and concrete in case of bad influence on sewage air pump performance when starting.

5.For easy maintenance and safe use, install a regulating valve on the outlet pipe and a pressure gauge near the outlet to guarantee the normal operation within the rated performance range, which lengthens the lifetime of sewage treatment plant air pumps.

6.Rotate the impeller from the suction side after installation. Disassemble the pump and find out the reasons if there is friction or stuck pump.

7.The processes of wastewater treatment plant in pump installation can be divided into three types, movable type, fixed type and coupling type

Recommended accessories:

Disc Diffuser

Tube Diffuser

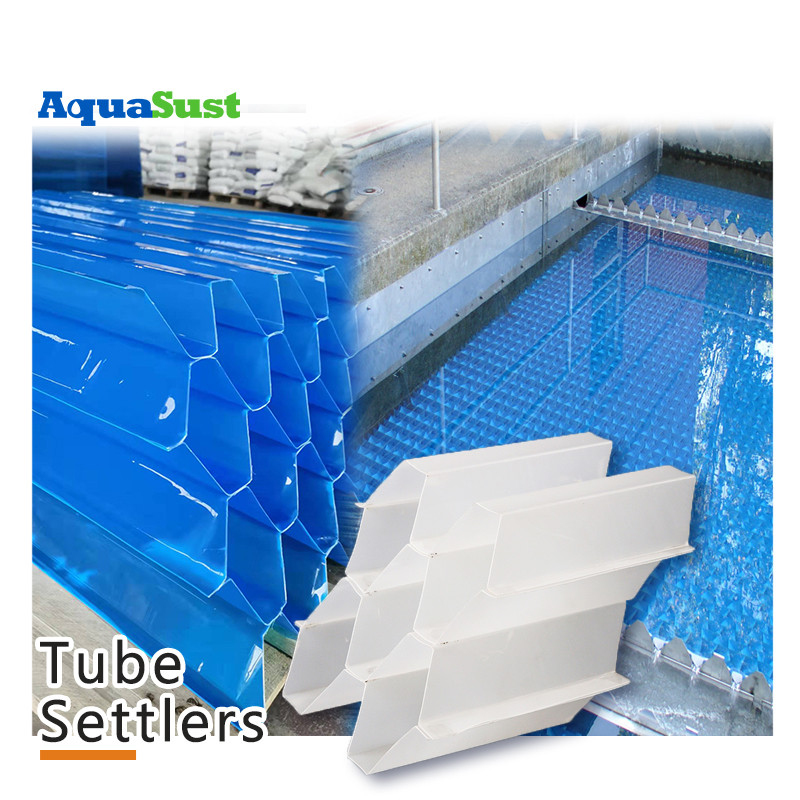

Tube Settler

Dewatering Machine